As Chinese automakers pour money into autonomous vehicles (AVs), they’re relying on another emerging technology to be the eyes of self-driving cars: lidar. Chinese carmakers are promising that models with lidar will hit the road in the next six months, likely marking the first time the tech sees widespread commercial deployment.

What is lidar? Well, it’s a lot like radar, but it uses lasers. It can pick out details and see small things better—a small dog crossing the road, a pothole. It can see things other systems, such as cameras and radar, might miss.

Drive I/O

Drive I/O is TechNode’s ongoing premium series on the cutting edge of mobility: EVs, AVs, and the companies trying to build them. Available to TechNode subscribers.

But established lidar systems are bulky contraptions that are proving hard to integrate into consumer cars. They’re expensive, too, driving up the price of cars that use them for self-driving functions. For now, it’s mostly seen on prototype robo-cars.

Despite the challenges, most Chinese AV contenders are counting on lidar.

Five Chinese lidar startups say that they’re close to making it work. It’s a tough act: the device has to be small enough to fit in a sedan, reliable enough to trust on the road, and cheap enough to fit into the price of a consumer car. While they won’t be the first to deliver road-ready systems, Chinese companies could be the first to do it at a practical price.

In this week’s issue, we’ll meet China’s leading lidar players and see how they’re trying to make the emerging technology work.

What is Lidar?

Lidar, or “light detection and ranging,” works similarly to radar, except it uses lasers instead of radio waves. Lidar’s range is more limited than radar, but it offers more precision about the shape of detected objects.

Originally used by NASA to track spacecraft and satellites in the 1960s, the technology has been used for archaeological and manufacturing purposes, among others, but is relatively new to the world of autos. It was first utilized in a driverless vehicle race called the DARPA Grand Challenge in 2004.

Compared to radar, Lidar can create a more accurate, more detailed 3D map of the world. Compared to cameras, it works better in low-light conditions.

Lidar is therefore seen by most AV designers as a critical safety layer that will enable AVs to drive in various traffic conditions, in combination with other sensors like radar and cameras.

However, the technology is still immature, meaning high costs and challenges with size and reliability. A minority of AV projects are therefore not using lidar. The most vocal lidar skeptic is (who else?) Elon Musk, who has promised self-driving cars with a camera-only “pure vision” approach. Tesla recently removed radar from its vehicles.

Mechanical spinning lidars are so far among the most commonly used for AV test fleets. These are typically perched on car roofs, with a set of rotating laser sensors housed in a cone to provide 360-degree vision. The technology is too cumbersome and unreliable for production vehicles. Its components are also prone to damage on bumpy roads. As a result, lidar makers are transitioning to so-called “solid-state,” or “lidar-on-a-chip” devices, which are more compact and use fewer moving parts.

Robo ski-racks

Most lidar systems on the road today are mechanical spinning lidar on AV prototype vehicles. You’ve probably seen one—they’re the ones that look like half a jetski, or three portly Alexas strapped to a ski rack. If you saw it in China, it was probably made by Hesai, the Baidu-backed startup that’s the dean of the field.

Hesai has dominated the experimental generation in China, making the systems used on most Chinese and some international prototypes. At least 10 out of the top 15 robotaxi startups worldwide are reportedly (in Chinese) among its clients, including Baidu, Didi, and Pony.ai.

But to address size and durability, lidar makers are now turning to “solid state” sensors that eliminate most moving parts. These can fit the system into a small box, around the size of a lunch box, which fits easily into the grill or tucks under the roof of a car. But miniaturization creates new problems with range, price, and reliability.

In early 2019, Hesai unveiled its latest solid-state device, called Pandar GT and boasting a detection distance of 300 meters, but it is still validating the product and negotiating with auto clients, according to a prospectus filed by the company in January.

So far, Hesai hasn’t found a customer to put its solid state technology into a production vehicle. Baidu, a leader in China AV tech, has skipped lidar for its self-driving package, known as Autonomous Navigation Pilot, despite years of collaboration with Hesai in mechanical lidars for its test fleets. Speaking to Chinese media during this year’s Auto Shanghai expo, Baidu’s vice president Wang Yunpeng said the company is developing a “reliable and affordable” lidar sensor for production cars with partners, without giving further details.

Key Chinese players at a glance

Hesai: Founded in 2014, it supplies lidar to Chinese self-driving players including Baidu, Didi, and Pony.ai. It has raised more than $530 million from investors including Baidu, Bosch, and Xiaomi.

Huawei: The tech giant started making lidars in 2015 and has formed partnerships with Chinese legacy automakers including BAIC and Changan.

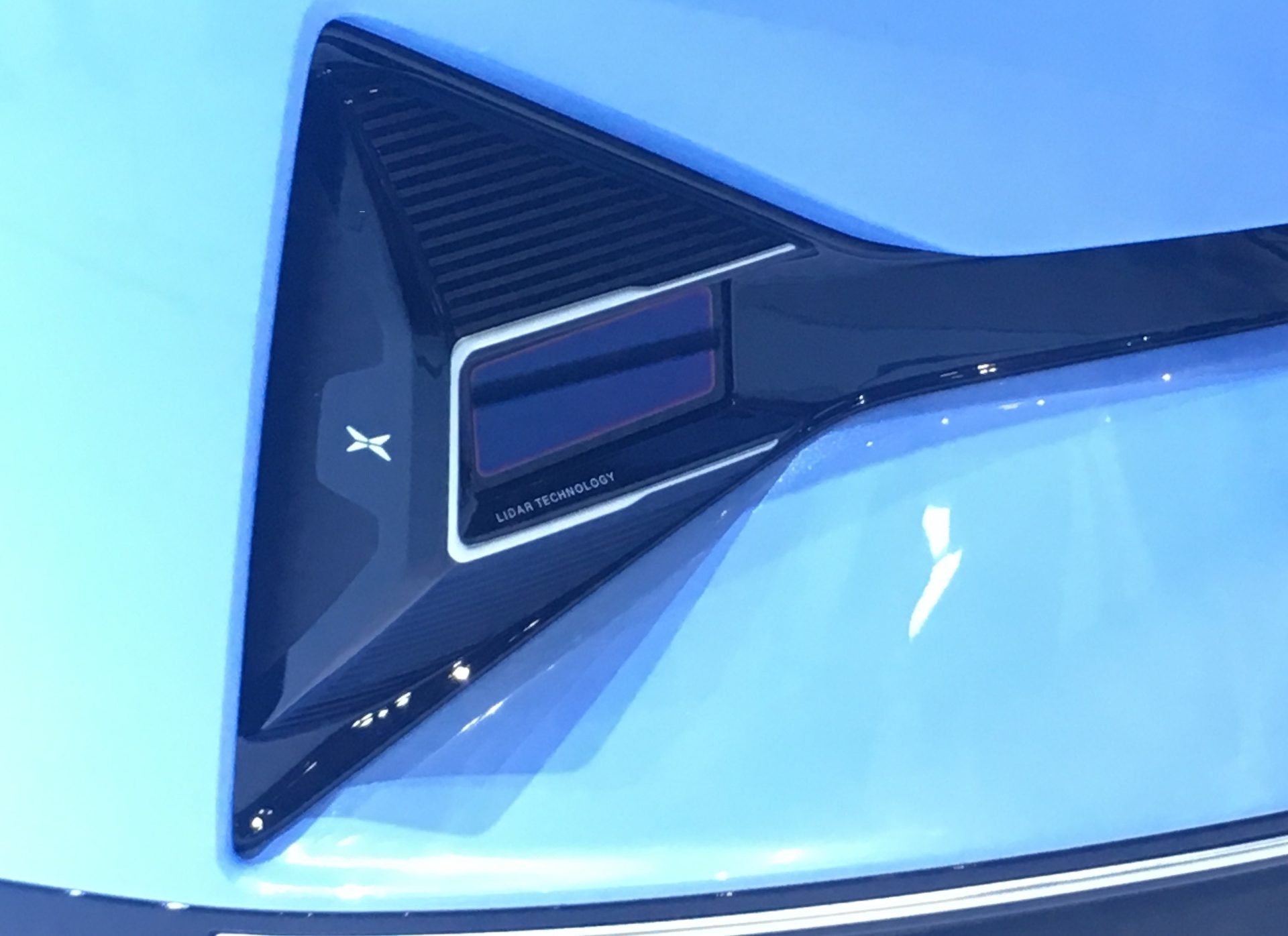

Livox: Incubated by drone maker DJI in 2016, Shenzhen-based Livox early this year became a partner to Chinese EV upstart Xpeng Motors. No funding information has been disclosed.

Innovusion: A Nio-backed company was set up by two former Baidu scientists Baidu in Sunnyvale, California in 2016, Innovusion has raised $94 million from investors including Nio Capital and Temasek.

Robosense: A Shenzhen-based company founded in 2014. It has raised $45 million from auto and tech names including Alibaba and SAIC.

Other key names: Major global manufacturers include Velodyne, the company which developed the first spinning lidar sensor specifically for testing AVs in 2005, as well as Valeo, partner of Audi for its A8 sedan, the world’s first production car to be equipped with a mechanical lidar. Several upstarts are also poised to raise money from public markets, including Luminar, a supplier to Tesla, and Israel’s Innoviz.

The key challenges

Five Chinese companies have made real progress on consumer-ready lidar, using a variety of approaches that strike different balances between range, price, and reliability, and reaching deals with major automakers to put their sensors into cars. But they each have difficult technical problems to solve.

Huawei and Robosense, a Chinese lidar upstart backed by Alibaba, are betting on a technology called micro-electro-mechanical systems (MEMS), which uses a tiny mirror (1 mm to 7 mm in diameter) to steer light. With only this piece of glass moving, the whole unit can be smaller than one that has to rotate as a whole. Robosense is currently making lidar s¯ensors for US electric vehicle startup Lucid Motors.

Both MEMS players are struggling with range: the latest offerings from the two companies only work at distances up to 150 meters.

Experts believe self-driving systems will need to spot objects at least 200 meters away to have enough time to react.

The MEMS solution has proven to be superior in terms of size, speed, and cost over other types of lidar sensors, according to an article published by three University of Florida engineers last year. However, a short detection distance due to the small mirror is a key flaw and, to deal with it, systems will likely need a larger detector, complicating assembly, the paper said.

With its latest offering boasting an impressive distance of 250 meters, Sunnyvale and Suzhou-based Innovusion seem to have solved the range issue. Their solution uses lasers at a wavelength of 1,550 nanometers, rather than more common 905-nm lasers. Considered a “sweet spot” by lidar developers, 1,550-nm light allows longer-range measurement and poses less danger to human eyesight. When using 905-nm lasers, power is usually restricted to avoid blinding people.

But Innovusion has faced challenges with production, for a physical reason: traditional silicon chips can’t detect 1,550-nm light, and therefore developers have to make custom sensors with an exotic material called indium gallium arsenide (InGaAs), which is more costly and more complex to manufacture. Setting up a production line for this less common technology is no easy feat, and the product may not be cheap.

Speaking at an online conference in March, Innovusion technology chief Li Yimin said getting lidars to work well on production cars had turned out to be more difficult than he expected. Nonetheless, he said his staff have been working “day and night” to meet the early 2022 timeline target set by partner Nio. The Chinese EV maker has promised to deliver its first sedan model enabled with its lidar sensors, the ET7, early next year.

“We have to pull ahead the production schedule of many advanced technologies including lidar … This has posed a lot of pressure on our teams and the partners. We are fully focused on achieving this goal and pushing ahead despite all those challenges,” Nio’s chief executive William Li said during an April earnings call.

Xpeng Motors, with partner Livox, claims it will be the first Chinese automaker to deploy lidar on production cars this October. But it is facing other problems. Livox’s sensors boast a unique method of scanning objects in a spiral or flower pattern, rather than in traditional horizontal linear scanning patterns. This helps its sensors create a higher-definition map of the world and could enable more reliable autonomous driving capabilities, the DJI-backed lidar maker has claimed.

However, the unusual scanning style requires the sensor’s motor driver to operate at a high rotation speed of over 6,000 revolutions per minute, more than five times that of sensors made by major French lidar marker Valeo. These speeds pose a big technical challenge for the five-year-old startup to meet reliability requirements for autos, since high rotational speeds usually come along with high abrasion and reduced lifetime for motors.

Livox recently said that it has resolved the issue with manufacturing improvements, based in part on DJI’s expertise in mechanical engineering from making drones, according to a Chinese media report published last week. However, Xpeng CEO He Xiaopeng last month during an earnings call acknowledged that the company is still testing lidars from multiple suppliers and is “very open” to other choices for new models scheduled for launch over the next two years.

“With an all-round sensing performance on our cars and our production capabilities, we’re very confident that we can be complementary to some of the disadvantages of lidar technology,” He added.

Some Chinese automakers and lidar startups are also seeking overseas partners. In addition to the Robosense-Lucid hookup, Chinese legacy automaker Great Wall Motors, a manufacturing partner of BMW, has teamed up with Germany’s Ibeo as its source for lidar sensors on production cars.

The price is right

After technical barriers, lidar-enable cars will have to leap another hurdle: cost. The sensors don’t come cheap.

China’s low-cost manufacturing advantage appears to apply to lidar, with the offerings of local suppliers usually costing 80% less than international competitors, or below $1,000, French market intelligence firm Yole Développement wrote in a report published last August.

However, lidar cars don’t look cheap. The latest premium electric sedan announced by Huawei and BAIC in April, equipped with three lidar sensors, has a starting price of RMB 388,900 ($60,785), more than 50% higher than that of Tesla’s locally-built Model 3.

R&D and onboard computing could be driving the cost. The Chinese telecom giant in April announced that it will double its annual auto R&D budget for self-driving cars to $1 billion this year, without giving a breakdown of its investments. Apart from three lidar sensors, the hardware stack of the BAIC-Huawei sedan also includes five more cameras, and five more radars than a Tesla Model 3’s. Although cameras usually take significant computing power in the vehicle, the task of combining data from multiple sensors also requires much computing power and a more complex vehicle architecture.

Mixed opinions

Not everyone agrees that AVs will need lidar. Tesla has been heavily relying on a cheaper, camera-based approach. Nissan and Baidu, are also skipping lidar, relying on cameras, radar, and ultrasonic sensors for AVs.

Most other major players, including Google’s Waymo and General Motor’s Cruise, consider lidar an essential part of developing safe autonomous cars. “Lidar sensors contribute to the redundancy and overlapping capabilities needed to build a car that operates without a driver, even in the most challenging environments,” wrote Cruise CTO Kyle Vogt in a post in 2017.

Chinese EV makers are betting on the lidar-based approach in competing against Tesla, and have gained chances to validate the technology. “At the current stage our top priority is not to secure as many contracts as possible, but to fine-tune our products and hit volume production,” (our translation) a Livox spokesperson told TechNode last month.

But lidar prices are falling. As the sensors get cheaper, the case for them looks more and more tempting. “Lidar guarantees high reliability for self-driving cars when vehicle autonomy is still in its early stage. Such redundancy is worth taking in the name of safety,” (our translation) Paul Gong, a China auto analyst at UBS, told TechNode last month.